The world of digital printing has undergone a revolutionary evolution in recent years. The floor printing printer is one of the most important representatives of this evolution. Offering an innovative solution for professionals struggling with the limitations of traditional printing techniques, these printers attract great interest, especially at the intersection of UV printing and 3D printing technologies.

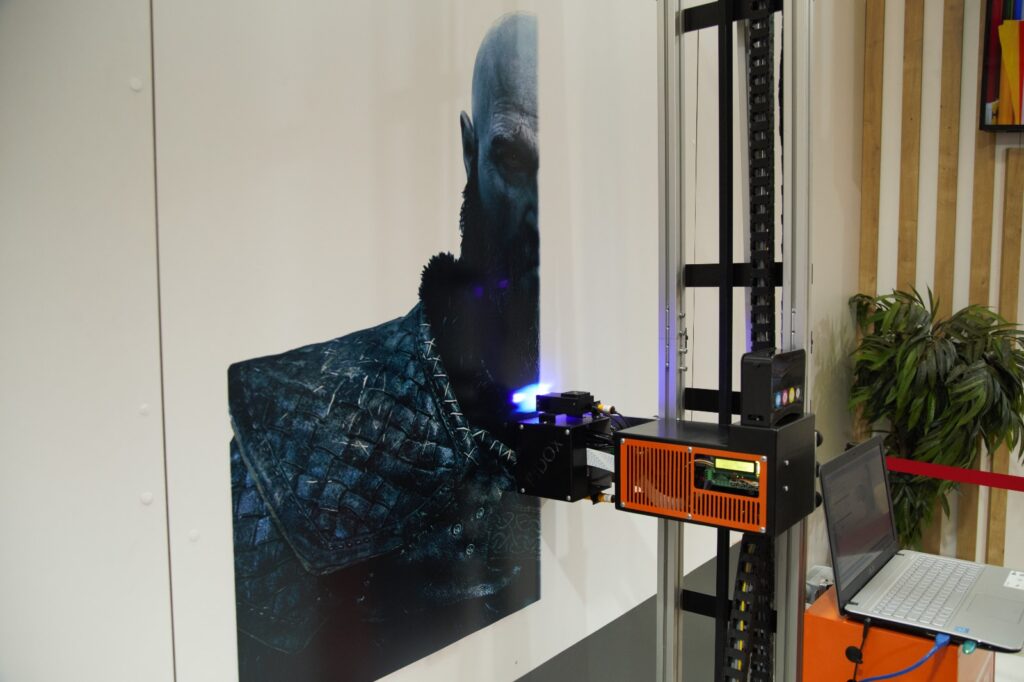

A floor printing printer is a printer, usually designed for industrial use, with the ability to print directly onto floors or other large surfaces. These printers are used in many areas such as advertising, interior design and event organisation. Thanks to UV printing and 3D printing technologies, it is possible to realise printing projects that were previously difficult to imagine.

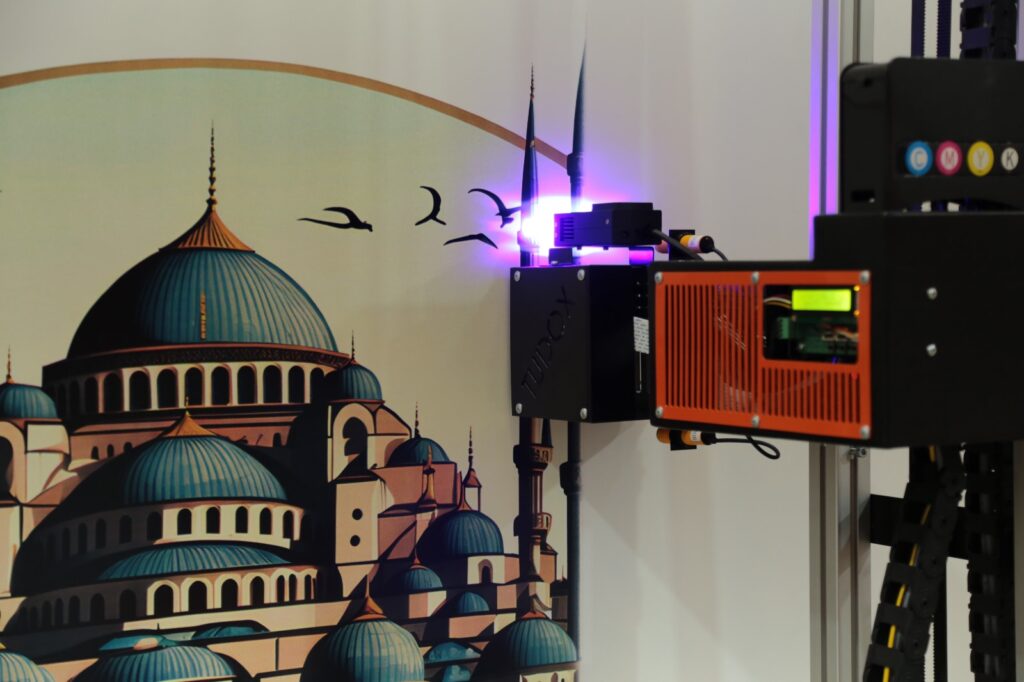

UV printing works on the principle that ultraviolet rays dry the ink instantly. This technique allows the print to dry immediately, which improves print quality and ensures that the print is more resistant to fading or distortion.

Thanks to the UV printing technology in the floor printing printer, excellent details and vivid colours are achieved on the floors. Especially in commercial areas, durability and longevity are essential. UV printing meets these needs, making the floor printing printer indispensable in the industry.

3D printing works on the principle of creating three-dimensional objects layer by layer. The use of 3D printing technology in the floor printing printer allows three-dimensional effects and textures to be added to floors. This is a great advantage for creating unique and eye-catching floors, especially in interior design.

Thanks to its 3D printing capability, the floor printer has the potential to go beyond traditional printing techniques to offer customers customised and creative solutions.

The introduction of the floor printing printer equipped with UV printing and 3D printing technologies has changed expectations and standards in the industry. The quality, speed and flexibility these printers offer have opened new doors for advertising and design professionals.

UV printing technology is an environmentally friendly alternative to traditional solvent-based inks. It creates less waste and minimises the release of harmful emissions into the air. This is a great advantage for companies that attach importance to the principle of sustainability.

The cost-effectiveness of the floor printing printer is characterised by both the speed of the printing process and the ability to produce with little material waste. Thanks to the fast drying of UV inks, it is possible to move on to other processes immediately afterwards, which means time savings. 3D printing can add depth and texture to the surface without using specialised materials, which can further reduce costs.

One of the biggest innovations brought by the floor printing printer is the customisation capability. 3D printing technology ensures that every project is unique and special. Whether it is a company logo or an original work of art, you can realise your dream designs with a floor printing printer.

Furthermore, these printers make it possible to print complex and detailed patterns simply and quickly. It is both time-consuming and costly to realise such designs with traditional printing methods.

The floor printing printer, which has caused a revolutionary change in the printing industry, has a wide range of uses. So where are these printers used? Here are some prominent areas of use:

The wide range of uses offered by the floor printer shows that it is not just a printing tool, but an innovation that opens up new creative horizons for industries. These advances in technology allow users to use not only their work but also their imagination without limits.

It’s exciting to see how this technology will evolve further as the impact of the printing printer grows in many areas such as advertising, design, art and industry, as well as the printing industry. We look forward to seeing what the next innovative application or design will be.

No, our machine is portable and disassembled. You can carry it very easily.

You can set up and print with Tudox Wall Printer in just 15 minutes.

UV ink is used for Wall Printer.

You can work on almost any print surface. You can use it on wood, glass, metal, plaster and ceramics.

It may vary according to the color intensity of the applied surface. With 1 liter of ink, you can print on an average of 60-70 square meters.

It is permanent on the wall surface for an average of 4-8 years for indoors and 2.4 years for outdoors.

You can do business in schools, hotels, restaurants, cafes, clinics and many more.

Yes, we have a detailed and intensive training process from A to Z. Remember that you can contact us about anything.

For us, customer satisfaction is paramount. As Tudox Wall Printer team, we are at your side in any negativity that may happen to you. Our technical support service is unprecedented in this sector.

Tudox Wall Printer is a manufacturer company and we sell all kinds of spare parts, ink

Call us, WhatsApp us or send us an e-mail. We send you our price offer during the day and quickly send you the details.

Tudox Machine Limited Company

Manufactures and sells Wall Printing Machine.

Tudox Machine Limited Company

Manufactures and sells Wall Printing Machine.

Let us call you!

Fill out the form and our teammates will call you.

[email protected]

+90 542 694 8714

Yeni Mah. Gaziler Cd. No:10 Çayırova/Kocaeli/Turkey

Tudox Wall Printer © 2023. All Rights Reserved.

Design & Development & Digital Marketing by Renware

[email protected]

+90 542 694 8714

Yeni Mah. Gaziler Cd. No:10 Çayırova/Kocaeli/Turkey

Tudox Wall Printer © 2023. All Rights Reserved.

Design & Development & Digital Marketing by Renware

0

WhatsApp us

Formu doldurun, istediğiniz ürün veya ürünler için teklif alın.

Fill in the form and get an offer for the product or products you want.